CONCORD UNITED PRODUCTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CONCORD UNITED PRODUCTS P.LTD.

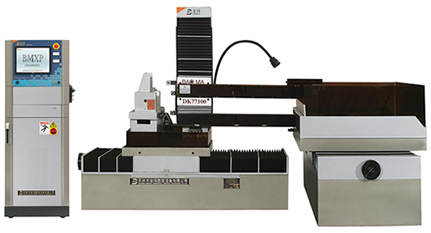

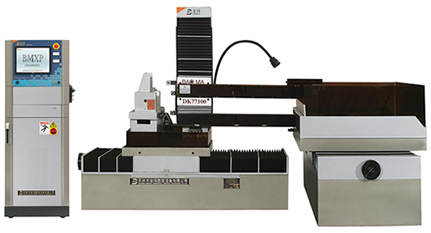

Cnc Wire Cut Edm Machines

| Technical Specifications | |||

|---|---|---|---|

| Model -> | DK-7763 | DK-7780 | DK-77100 |

| Table Travel X,Y Axis (mm) | 630 x 800 | 800 x 1000 | 1000 x 1200 |

| Work Table Size L x W (mm) | 660 x 1100 | 820 x 1400 | 1090 x 1600 |

| Maximum Work Piece Thickness (mm) | 500 | 500 | 500 |

| Maximum Taper / 100 mm Thickness |  3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

30° (Optional) 30° (Optional) |

30° (Optional) 30° (Optional) |

30° (Optional) 30° (Optional) |

|

| Maximum Work Piece Weight (kgs) | 3000 | 5000 | 5000 |

| Machine Weight (kgs) | 4500 | 6700 | 7000 |

| Controller Specifications | |||

| Display | LCD Display | ||

| Control System | CNC | ||

| PC | Industrial PC # | ||

| Axis Control | 4 - axes (X,Y,U,V) | ||

| X, Y Axis Guide Ways | Linear motion guide ways for X, Y axis | ||

| Resolution | 0.001 mm | ||

| Wire Dia | 0.18mm (Std.), 0.15mm, 0.12mm (Optional) | ||

| Interpolation | Linear and Circular | ||

| Programming | Incremental | ||

| Least Input Increment | 0.001 mm | ||

| Least Command Input |  0.001mm 0.001mm |

||

| Data Input / Output System | USB Port , Regular Keyboard and Mouse; Can read AutoCAD .dxf format | ||

| Input Power Supply | 3 Phase, 415 Volts, 50 Hz with Neutral and Earth | ||

| Total Machine Load | 1.5 KVA | ||

| Graphic Display | Graphic display of part showing wire position | ||

| Processing and Data Entry | Dual Screen, New programs can be entered while cutting previous programme | ||

| Auto Stop | Auto Shut-off at the end of program | ||

| Dielectric Fluid | Soft water (D.M Water) + Gel | ||

| Dielectric Tank Capacity | 55 Litres | ||

| Standard Features | |||

Note: Due to continuous engineering improvements, specifications are subject to change without prior notice * At Standard test conditions # Chasis |

|||

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.